News detail

BOVIPACK: What problems may occur with strapping machines?

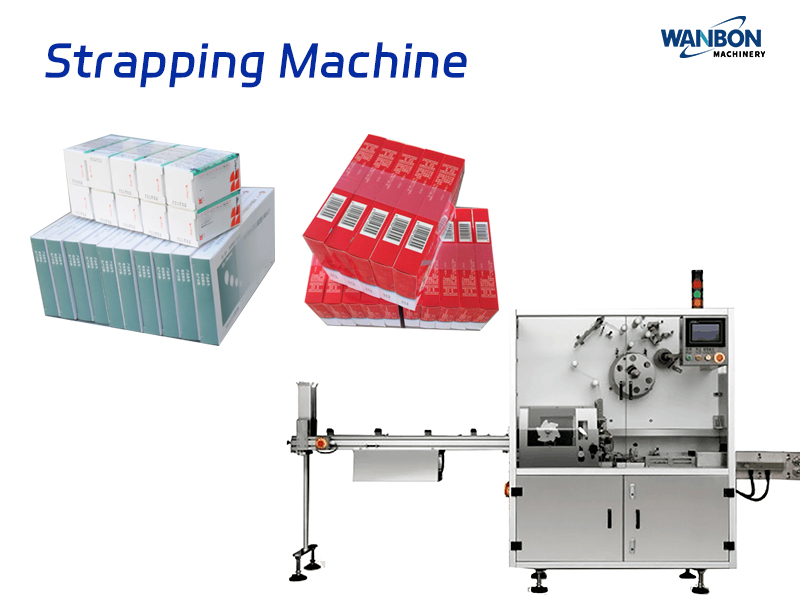

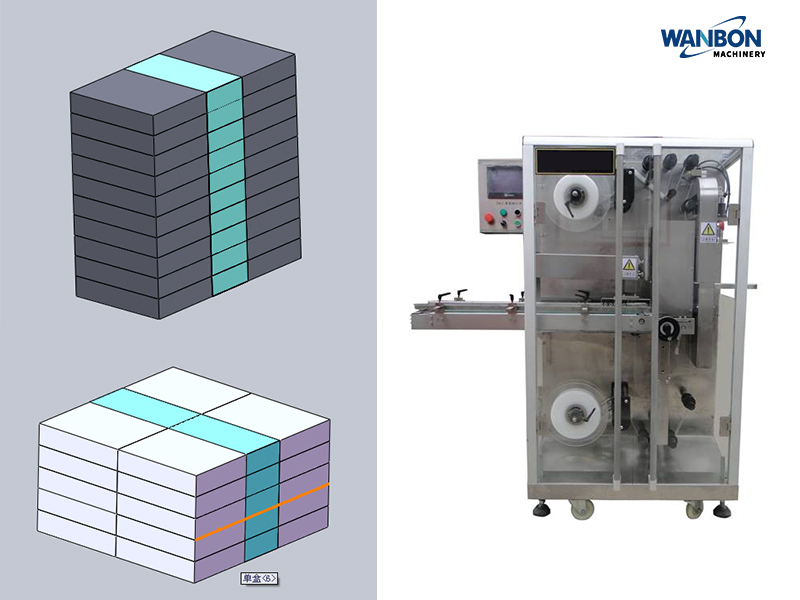

Strapping machines have become an essential tool in various industries for securing and bundling packages.

However, like any other machinery, strapping machines are not exempt from experiencing problems.

In this article, BOVIPACK will discuss some common issues that may occur with strapping machines and how to address them.

BOVIPACK: The Problems and Solutions of Strapping Machines

1. Jamming: Jamming can happen when the strapping material gets stuck in the machine during the strapping process.

This issue can be caused by various factors such as improper loading of the strapping material, worn-out parts, or a misaligned strapping guide.

Solution: To resolve this problem, it is important to ensure that the strapping material is properly loaded and that the machine’s parts are well-maintained.

Regular cleaning and lubrication of the machine can also help prevent jamming.

2. Tensioning failure: Tensioning failure occurs when the strapping material is not adequately tightened around the package.

This issue can be caused by a malfunctioning tensioning mechanism or an incorrect setting of the tensioning force.

Solution: To address this problem, it is crucial to regularly check the tensioning mechanism for any signs of damage or wear.

Adjusting the tensioning force according to the package’s requirements can also help ensure proper tensioning.

3. Sealing process: Sealing failure can occur when the heat sealing mechanism does not properly melt and seal the strapping material.

This issue can be caused by a faulty heating element, insufficient heat, or improper adjustment of the sealing temperature.

Solution: To fix this problem, it is necessary to inspect the heating element regularly and replace it if necessary.

Adjusting the sealing temperature to the appropriate level can also help ensure a secure seal.

4. Feeding mechanism: Feeding failure can occur when the strapping material does not feed properly into the machine, resulting in a disrupted strapping process.

This problem can be caused by a misaligned or worn-out feeding wheel, an incorrect feeding speed, or a buildup of dirt and debris in the feeding mechanism.

Solution: To resolve this issue, it is important to regularly clean and maintain the feeding mechanism.

Adjusting the feeding speed and ensuring proper alignment of the feeding wheel can also help prevent feeding failure.

In conclusion, while strapping machines are efficient tools for packaging and bundling, they may encounter various problems.

Jamming, tensioning failure, sealing failure, and feeding failure are among the common issues that can occur with strapping machines.

Regular maintenance, proper adjustment of settings, and prompt troubleshooting can help address these problems and ensure the smooth operation of strapping machines in various industries.

If you need the automatic overwrapping machine for your products, please feel free to contact me!

Send Inquiry

Copyright © 2025 Wanbon Boway Machinery Co., LTD. All rights reserved.

Chinese

Chinese Spanish

Spanish