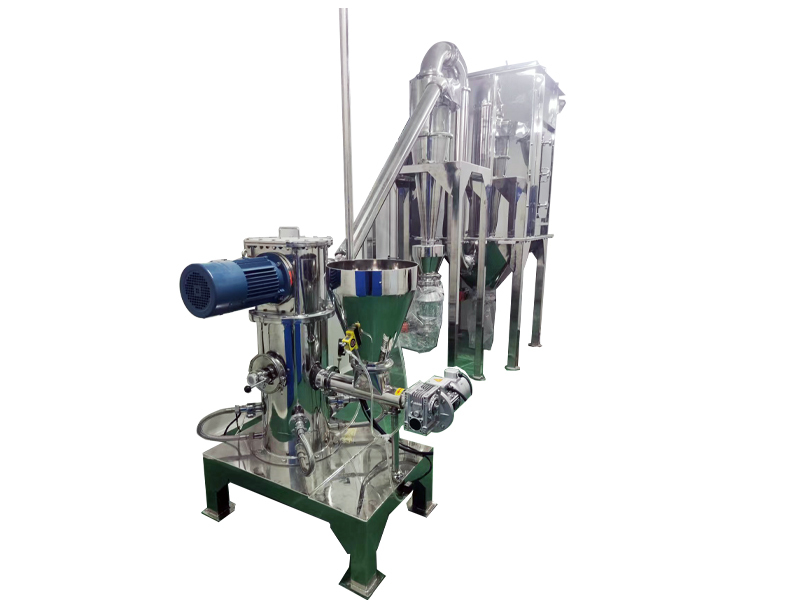

Fluidized Bed Type Air JET MILL

AIR JET MILL/GRINDER/PULVERIZER. Air JET MILL/Air flow crusher and cyclone separator, dust collector, induced draft fan to form a complete set of crushing system. Main application areas: lithium electric materials, chemical powder, pharmaceutical crushing, mineral ultrafine.

Email: [email protected]

Product detail

Fluidized Bed Type Air JET MILL

Air JET MILL Working Process

Air JET MILL/Air flow crusher and cyclone separator, dust collector, induced draft fan to form a complete set of crushing system. Compressed air after filtering and drying, through the Laval nozzle high-speed injection into the crushing chamber, in the intersection of multiple high-pressure airflow materials were repeatedly collision, friction, shear and crushed, crushed materials in the blower under the action of the pumping force of the upward movement of the airflow to the grading area, in the high-speed rotation of the grading turbine produces a strong centrifugal force, so that the coarse and fine materials are separated to meet the requirements of the particle size of fine particles through the grading wheel into the Cyclone separator and dust collector, coarse particles fall to the crushing area to continue crushing.

Characteristics of JET MILL/GRINDER/PULVERIZER

1.Suitable for dry crushing of various materials with Mohs hardness below 9, especially suitable for crushing of high hardness, high purity and high value-added materials.

2.Product particle size D97: adjustable between 2-150 microns, good particle shape, narrow particle size distribution.

3.Low-temperature media-free crushing, especially suitable for heat-sensitive, low melting point, sugar-containing and volatile materials.

4.Crushing process relies on the collision between the materials themselves to complete, unlike mechanical crushing rely on the impact of blades or hammerheads and other materials crushed, so the equipment is wear-resistant, high product purity.

5.Can be used in tandem with multi-stage classifier, a production of multiple particle size sections of the product.

6.The equipment is easy to disassemble and clean, and the inner wall is smooth without dead angle.

7.The whole system is sealed and crushed, less dust, low noise, clean and environmentally friendly production process.

8.Control system adopts programme control, easy to operate.

Technical Parameters of AIR JET MILL/GRINDER/PULVERIZER

| Paras/Specs | 03 | 06 | 10 | 20 | 40 | 60 | 120 |

| Feeding material

mm |

<3 | <3 | <3 | <3 | <3 | <3 | <3 |

| Product output size d97:um | 2~150 | 2~150 | 2~150 | 2~150 | 2~150 | 2~150 | 2~150 |

| Output capability

kg/h |

2~10 | 10~30 | 30~80 | 50~100 | 100~500 | 200~1000 | 500~2000 |

| Air consumption

m3/min |

3 | 6 | 10 | 20 | 40 | 60 | 120 |

| Air pressure

Mpa |

0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 |

| Installed power kw | 21 | 42 | 85 | 147 | 282 | 415 | 800 |

Ancillary products: unpacking machine, pipe chain conveyor, 25kg bag packaging machine, ton bag packaging machine.

![]()

Send Inquiry

Copyright © 2025 Wanbon Boway Machinery Co., LTD. All rights reserved.

Chinese

Chinese Spanish

Spanish