News detail

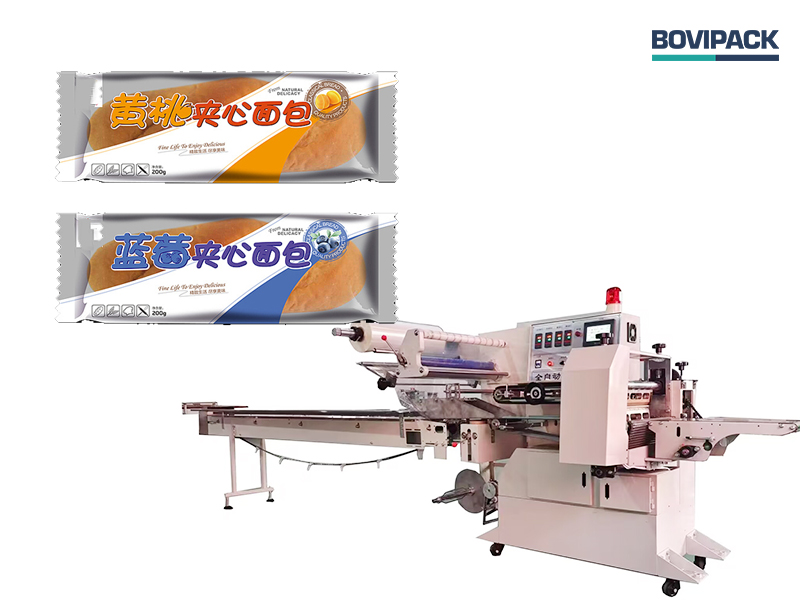

How to use Flow Wrapping Machine? Pillow wrapping machine instruction manual-2

The belowing content show that how to use the standard HFFS flow wrapping machines, including machine structures, and how to installation.

Flow Wrapping Machine Structural characteristics

1) Double frequency converter control, bag length is set and cut, no need to adjust the empty walk, one-step, save time and film.

2) Text-based man-machine interface, easy and fast parameter setting.

3) Fault self-diagnosis function, fault display at a glance.

4) High-sensitivity photoelectric eye colour-code tracking for more accurate sealing and cutting positions.

5) Independent PID control of temperature, better suited to various material wrapping.

6) Positioning stop function, no sticky knives and no film waste.

7) Simple transmission system, more reliable work, more convenient maintenance.

8) All controls are realised by software, which facilitates functional adjustments and technical upgrades, backward.

Flow Wrapping Machine Machine installation

1. Ground requirements

The machine should be installed on a level and solid surface with sufficient space reserved around the machine for operation and maintenance.

2. Environmental conditions

1) Temperature: The normal ambient temperature shall be 5℃ to 40℃.

2) Humidity: 30% to 90%.

3) Keep away from oil and gas, chemicals, acids, alkalis and explosives or flammable materials.

4) Ambient lighting: 300 LUX or more.

5) Avoid direct sunlight.

6) Avoid proximity to machines that generate vibrations.

7) Avoid direct fan blowing.

3. Installation steps

1) Firstly, determine the position of the mainframe, and use the working platform as a benchmark to adjust the four horizontal screws respectively to level and position the mainframe.

2) Install the feed conveyor so that it is bolted to the left end of the mainframe and leveled and positioned by adjusting the two horizontal adjustment screws of the feed conveyor. It is required that the bottom plane of the feeding trough is flush with the table surface of the main machine where it is connected to the main machine.

3) Install the push finger chain. Loosen the handwheel at the left end of the feed conveyor and then install and connect the push finger chain, adjust the handwheel to make the push finger chain loose and tight.

4) Mating power cord. This machine uses 220V single-phase, 50HZ power, it is strictly forbidden to connect 380V or other non-conforming power supply, please pay special attention to the user! To ensure safety, the connection must be done by an electrical professional and is supplied with a connection cable. If you are equipped with your own power plug, you must use a 1.5m² three-core cable to correctly connect the Live Wire(L), Neutral wire (N) and Earth wire(E).

4. Power feed test

1) Make sure that the supply power is correct (test with a test pen that the incoming power L and N are correct).

2) Close each circuit breaker in the control box, and observe whether the instruments and power signal lights on the control panel are normal.

3) Tap the jog button and observe if the machine is running normally.

4) By pressing the man-machine interface, set the packing speed to 40 packs/min, then press the start button (green) to run the machine normally for 3~5 minutes, after making sure the machine is normal, press the stop button (red). This completes the correct installation of the machine.

Send Inquiry

Copyright © 2025 Wanbon Boway Machinery Co., LTD. All rights reserved.

Chinese

Chinese Spanish

Spanish