News detail

How to use Flow Wrapping Machine? Pillow wrapping machine instruction manual-5

Pillow Bag Flow Wrapping Packaging Machine operation

1) Safety check. Check to make sure that there is no debris on the conveyor belt, on the work table, on the end seal knife, etc. and that no other people are operating the machine.

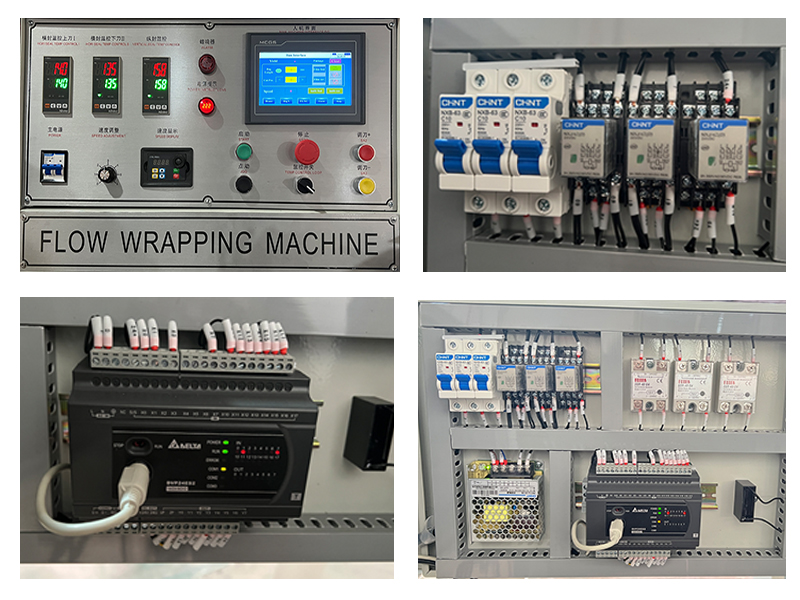

2) Turn on the power supply. Open the door lock of the electric control box, close the total circuit breaker, close the box door to observe whether the temperature controller display on the control panel is normal, whether the power signal light is normal display, whether the man-machine interface is normal display.

After the safety check and the power has been turned on properly, the machine needs to be operated as described below.

5.1. Human-machine interface

The main parameters of the machine are set through the HMI. After switching on the power, the HMI first displays the home page, the page is shown in Figure 6.

Press the (∨) key according to the on-screen instructions and the HMI will sound and go to the next screen.

(i) Parameter setting

Press; HMI Home; instructions, touch the (<= key to enter the; parameter setting; interface. Touch and press the (↑) key to return to the;HMI Home;screen.

1) Setting of “packing speed”. When the speed setting exceeds the rated range of the machine, an error message will be displayed and the machine will be asked to reset until the setting is correct.

2); Bag length; setting. When the bag length setting exceeds the rated range of the machine, an error message will be displayed and the machine will be asked to set again until the setting is correct.

3) Setting of “cut-off position”. According to the instructions of the interface, touch the (∨) key to enter the “cut-off position” setting screen, enter the value according to the screen instructions. Input the value of the confirmation, first of all in the case of cutting off the value of the parameters set to 0, empty bag sealing and cutting, measuring the size of the cut to the colour code L, and then the test size value into the “cut off position” parameters can be.

(ii) Counting

Press ;HMI Home; instructions and touch the (>) key to enter the ;Count; interface as shown.

The interface mainly records the machine’s accumulated working time, boundary count production and shift production, to facilitate user production management. The shift output can be cleared by touching the (SET) key to clear 0. Touch and press the (↑) key to return to the HMI home page;.

(iii) Tracking methods

Press ;HMI Home; instructions and touch the (∨) key to enter the ;Tracking Mode; screen as shown. Touch and press the (↑) key to return to the;HMI Home; Touch Press

(iv) Inflation setting (optional function)

Press the ;HMI Home; instructions and touch the (∧) key to enter the ;Inflation Settings; screen, as shown. Touch the (↑) key to return to the;HMI Home;.

1) “Inflation delay” setting. Press the “Inflatable setting” screen and press the (∧) key to enter the “Inflatable delay” setting screen, then enter the value according to the screen instructions. The size of the entered value should be determined by the inflation effect.

Touch the (↑) key to return to the ;inflation settings; screen.

2) “Inflation time” setting. Press the “Inflatable setting” screen, touch the (∨) key to enter the “Inflatable time” setting screen and enter the value according to the screen instructions. The size of the entered value should be determined by the inflation effect.

(v) Quantitative packaging

The machine has a quantitative packaging function. That is, when the quantitative packaging is turned on and the quantitative packaging quantity is set, at this time, the packaging machine is started and the packaging machine is packed according to the normal state, and when the packaging quantity reaches the set packaging value, the packaging machine is automatically stopped. In this way, it is easy to measure and handle the finished packaging product.

When the packaging machine is stopped midway, it is started again, at which point the quantitative packaging starts measuring from zero.

Press; HMI Home; instructions, touch the (CLR) key to enter the; Dosing and Packaging; interface as shown. Touch the (ESC) key to return to the;HMI Home;screen.

Touch Press

To set the “quantity setting”. Press the ∧ key to enter the “Dosage setting” screen and enter the value according to the instructions on the screen. The size of the input value should be determined according to your needs.

Touch the (ESC) key to return to the; Dosing and Packaging; screen.

5.2. Temperature control

The flow wrapping machine has two sets of temperature control system, which control the middle seal temperature and the end seal temperature respectively. The size of each temperature setting depends on the speed of the packaging, the thickness of the film and the ambient temperature of the surroundings. zui suitable setting value should be appropriate for the middle seal and end seal not to leak air and not to scorch and wrinkle. The operation of the thermostat is described in the manual of the thermostat.

5.3. Colour-coded electric eye

For products requiring tracking cuts, a colour-coded electric eye is necessary. After the wrap has been fitted, the position of the colour-coded electric eye is adjusted so that the beam emitted by the eye is aligned with the place where the colour-code passes, as shown in Figure 19.

The sensitivity of the colour-coded electric eye is adjusted at the factory, if you still need to adjust it, please refer to the instruction manual of the supplied electric eye.

5.4. Start-up

1) Point movement

Pressing the jog (black) button causes the machine to run at a speed of 30 (packets per minute) for the duration of the press, and stops immediately when the button is released.

2) Linkage

By tapping the start (green) button, the machine will move continuously at the set speed until the stop (red) or emergency stop (mushroom head) button is pressed.

5.5. Shutdown

1) Normal shutdown

Pressing the stop (red) button will stop the machine in the horizontal position of the end sealer.

2) Emergency shutdown

Pressing the emergency stop (mushroom head) button will stop the machine instantly and to start it again, the button must be reset.

Send Inquiry

Copyright © 2026 Wanbon Boway Machinery Co., LTD. All rights reserved.

Chinese

Chinese Spanish

Spanish