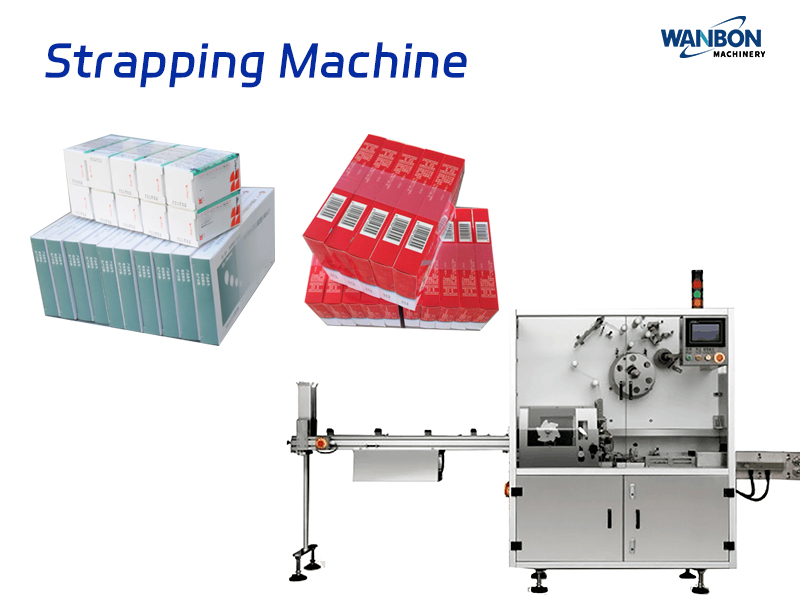

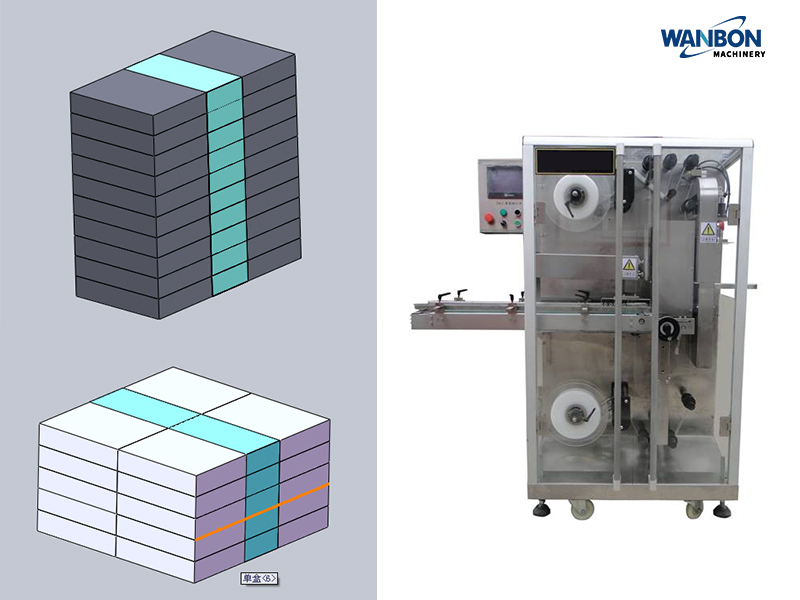

Pharmaceutical Box Strapping Machine for Group Binding

Strapping machines play a crucial role in streamlining packaging processes across various industries. These automated devices are designed to securely bind and bundle products together using straps or bands, enhancing the efficiency of packaging operations.

Email: [email protected]

Product detail

Pharmaceutical Box Strapping Machine for Group Binding

Strapping machines play a crucial role in streamlining packaging processes across various industries. These automated devices are designed to securely bind and bundle products together using straps or bands, enhancing the efficiency of packaging operations.

Pharmaceutical Box Strapping Machine Features:

1. Automated Operation:

Strapping machines are equipped with advanced automation features, allowing for efficient and consistent strapping of packages. Automated tensioning, sealing, and cutting processes contribute to a faster and more reliable packaging workflow.

2. Adjustable Tension Control:

The tension of the straps is a critical factor in ensuring the stability and safety of packaged goods. Strapping machines offer adjustable tension control, allowing operators to customize the strapping tension based on the specific requirements of the products being packaged.

3. Versatility in Strap Material:

Strapping machines are designed to accommodate various strap materials, including plastic and steel. This versatility ensures that businesses can choose the most suitable strapping material based on the type of products being packaged and their transportation needs.

4. High-Speed Strapping:

With their automated processes and advanced technology, strapping machines can achieve high-speed strapping, significantly improving the overall packaging efficiency. This feature is particularly beneficial for industries with high-volume packaging demands.

5. User-Friendly Interface:

Most strapping machines are equipped with user-friendly interfaces that simplify operation and minimize the learning curve for operators. Intuitive controls and touchscreens contribute to a seamless and efficient user experience.

Send Inquiry

Copyright © 2025 Wanbon Boway Machinery Co., LTD. All rights reserved.

Chinese

Chinese Spanish

Spanish