Pipe Chain Conveyors with Professional Design

Pipe chain conveyor is also known as pipe conveyor, chain pipe conveyor and so on. It is widely used in various industries such as chemical industry, chemical fibre, pesticide ore, plastic, rubber, grain, coal powder, food industry, building materials and so on.

Email: [email protected]

Product detail

Pipe Chain Conveyors with Professional Design

Pipe chain conveyor is also known as pipe conveyor, chain pipe conveyor and so on. It is a mechanical system with movement inside the closed tube, which has the features of stable performance, energy saving, environmental protection and sealing in the conveying system. It can continuously convey bulk materials such as powder, paste, small granules and small lumps, etc. It can also be transported horizontally, inclined and vertically in combination. It is widely used in various industries such as chemical industry, chemical fibre, pesticide ore, plastic, rubber, grain, coal powder, food industry, building materials and so on.

Application areas of CHAIN PIPE CPNVEYORS

1. Fine chemical industry: pigment, dyestuff, paint, carbon black, titanium dioxide, iron oxide, ceramic powder, heavy calcium, light calcium, bentonite, molecular sieve, kaolin, silica powder, activated carbon and so on.

2.Pesticide ores: urea, ammonium chloride, ammonium bicarbonate, bicarbonate of soda, solid pesticide, tungsten powder, pesticide auxiliaries, copper concentrate powder, coal powder, phosphorus powder, alumina powder and so on.

3.Building materials: cement, clay, yellow sand, quartz sand, clay powder, silica, limestone powder, dolomite powder, wood chip powder, glass fibre, silicon dioxide, talcum powder, etc.

4.Food industry: flour, starch, cereals, milk powder, food additives, etc.

Characteristics of PIPE CHAIN CONVEYOR

1、Compact structure, small space occupation, can change the conveying direction in three dimensions.

2、Totally enclosed conveying, no dust spillage, no need to set dust collector at the outlet. It can be filled with gas when conveying materials.

3、Materials are transported smoothly along the tube, with less material breakage, and the slow curve conveying makes few material particles produce debris.

4、Lowest energy consumption – the most economical running cost, the whole system has only one motor to drive.

5、Not produce system blockage – suitable for conveying a variety of forms of materials.

Pipe chain conveyor Technical parameters

| MODEL | Delivery Capacity

(m3/h) |

Sprocket speed (r/m)

|

Chain plate line speed

(m/s) |

Motor power (kw)

|

| GL80 | 4 | 20 | 0.29 | 4 |

| GL100 | 8 | 18 | 0.31 | 5.5 |

| GL150 | 16 | 15 | 0.31 | 7.5 |

| GL200 | 28 | 12 | 0.3 | 11 |

| GL250 | 48 | 10 | 0.3 | 15 |

| GL300 | 60 | 8 | 0.28 | 18.5 |

| GL400 | 80 | 8 | 0.28 | 22 |

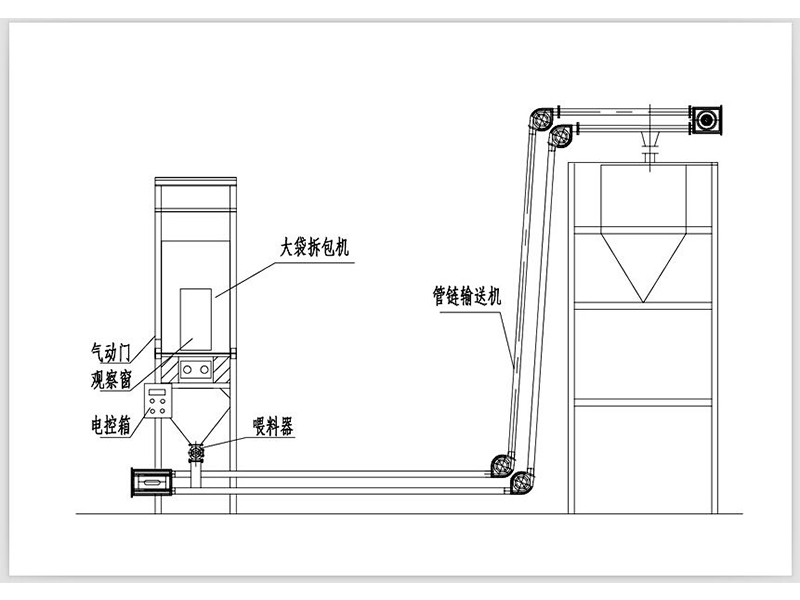

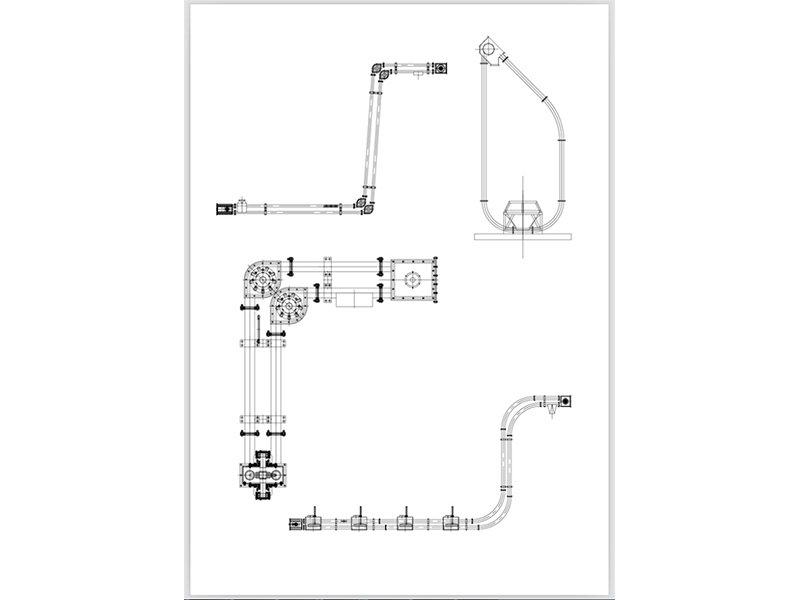

Pipe chain conveyor production line design

Send Inquiry

Copyright © 2025 Wanbon Boway Machinery Co., LTD. All rights reserved.

Chinese

Chinese Spanish

Spanish