Smallest Box Size Bopp Packaging Machines Wanbon BOVIPACK

Smallest Box Size BOPP Packaging Machines represents a significant leap forward in the packaging industry. The smallest thickness is 4.5mm. Like razor blades, cigarette filters, erasers... choose WANBON BOVIPACK,you will enjoy the best services!

Email: [email protected]

Product detail

Smallest Box Size Bopp Packaging Machines Wanbon BOVIPACK

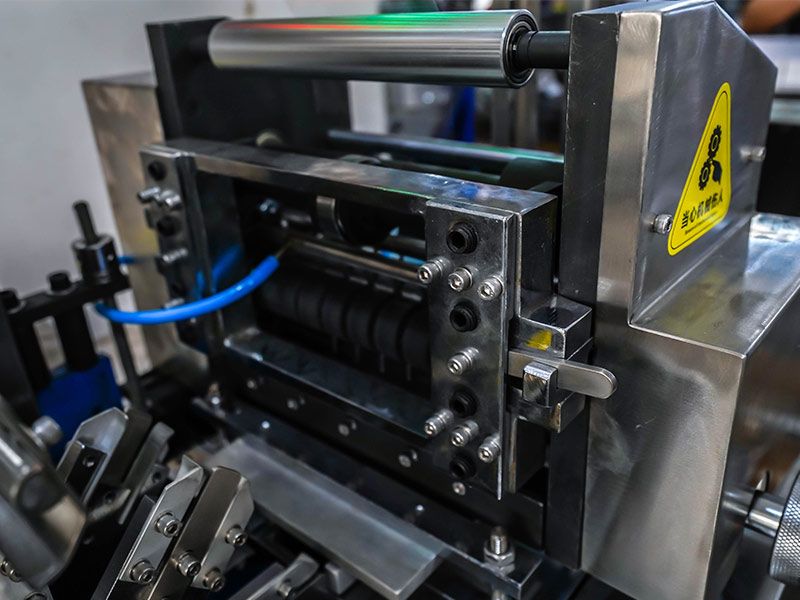

BOPP packaging has long been a popular choice for its exceptional clarity, high tensile strength, and moisture resistance. However, the conventional packaging machinery often fell short in terms of size, resulting in excessive material wastage and compromised efficiency. The advent of Smallest Box Size BOPP Packaging Machines marks a paradigm shift in the industry, offering a solution that not only enhances productivity but also aligns with environmental sustainability goals.

Cellophane Wrapping Machine Key Features:

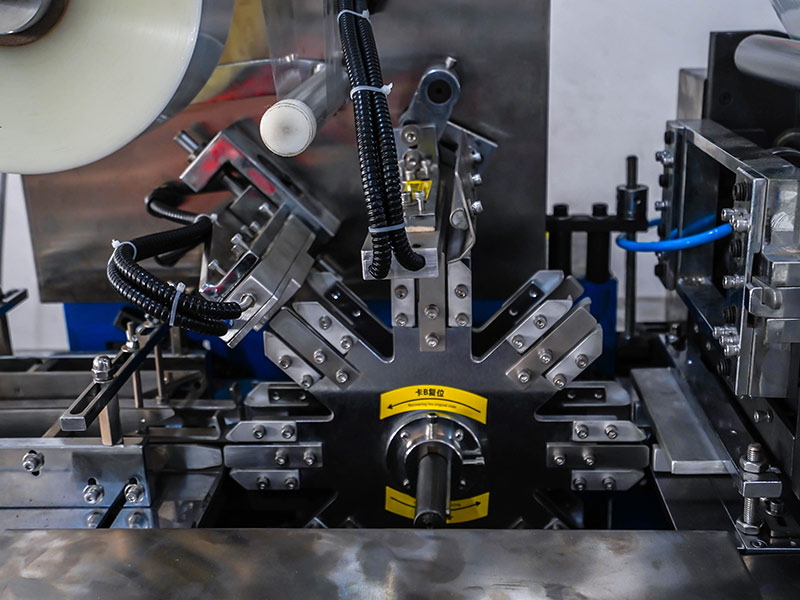

- Compact Design: The compact footprint of these machines allows businesses to maximize their floor space, a crucial factor in industries where every square meter counts. Smallest Box Size BOPP Packaging Machines redefine spatial efficiency without compromising on performance.

- Advanced Automation: Leveraging cutting-edge automation technology, these machines ensure a seamless and streamlined packaging process. From film cutting to sealing, every step is meticulously controlled, reducing human intervention and minimizing the margin of error.

- Material Optimization: One of the standout features is the precise utilization of BOPP film. The machines are engineered to minimize excess material usage, resulting in cost savings and a substantial reduction in environmental impact. This aligns with the growing global emphasis on sustainable and eco-friendly packaging practices.

- Customization Capabilities: Smallest Box Size BOPP Packaging Machines are versatile and can be tailored to meet specific packaging requirements. Whether it’s adjusting box dimensions or accommodating different film thicknesses, the machines provide a high level of customization to suit diverse industry needs.

Bopp Overwrapping Machines Benefits:

- Cost Efficiency: By optimizing material usage and reducing waste, businesses can achieve significant cost savings in their packaging operations. The initial investment in Smallest Box Size BOPP Packaging Machines is quickly offset by long-term financial gains.

- Environmental Impact: The machines contribute to a more sustainable future by promoting responsible resource consumption. The reduction in material waste not only benefits the bottom line but also aligns with corporate social responsibility initiatives.

- Enhanced Productivity: The advanced automation features of these machines result in faster and more efficient packaging processes. This leads to increased overall productivity, allowing businesses to meet growing market demands with ease.

Send Inquiry

Copyright © 2025 Wanbon Boway Machinery Co., LTD. All rights reserved.

Chinese

Chinese Spanish

Spanish