Turning Pipe Chain Conveyors

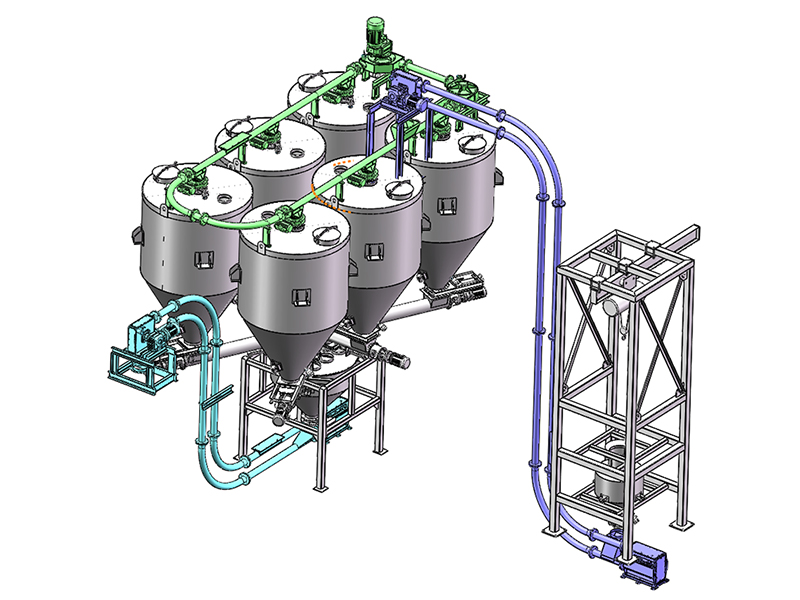

This turning pipe chain conveyor can carry out continuous transportation of bulk materials such as powder, small particles and small pieces, and can achieve horizontal, slope, vertical and other ways of material transportation, and can be combined with other material handling systems for system transportation.

Email: [email protected]

Product detail

Turning Pipe Chain Conveyors

Turning pipe chain conveyor is a type of pipe chain conveyor equipment in the market at present. This turning pipe chain conveyor can carry out continuous transportation of bulk materials such as powder, small particles and small pieces, and can achieve horizontal, slope, vertical and other ways of material transportation, and can be combined with other material handling systems for system transportation.

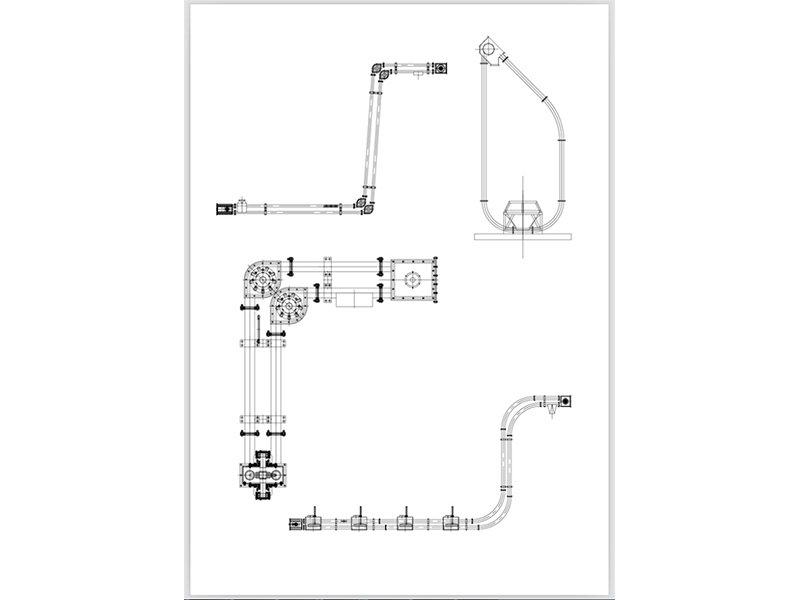

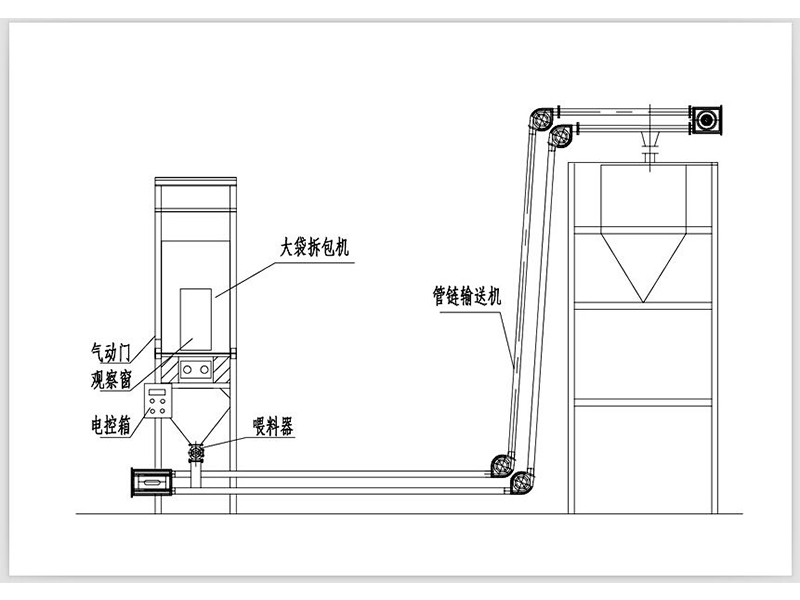

In the process of material conveying, the material can be in the sealed pipe of the equipment, the material is moved by the transmission of the chain piece in the equipment, and the direction of moving is along the turning pipe for inclined, horizontal or vertical.

In the vertical conveying, the material will be driven by the rising thrust of the chain piece after entering into the material inlet, coupled with the chain piece and the obstruction of the pipeline can be very good to make the material along the pipeline for vertical upward conveying.

In the process of horizontal conveying, the same material will be subject to the horizontal thrust of the chain piece after entering into the inlet. This will prompt the material to be conveyed horizontally along the pipe.

Pipe Chain Conveyor Features

1、Volumetric conveying device, can achieve the material conveying and measurement. It is easy to realise centralised control, improve automation and meet the requirements of modern enterprises on environmental protection.

2、Compact structure, small space occupation, can change the conveying direction in three dimensions.

3、Materials to be conveyed from the inlet to the outlet flange is in a closed state, the outlet does not need to set up a dust collector, when conveying materials can be filled with gas, no dust leakage into the environment during transport.

4、Materials are transported smoothly along the pipe, basically there is no internal movement, so the material breakage is less, and the slow curve conveying makes few material particles produce debris.

5、According to different feeding situations, the inlets can be more than 10 metres away from each other.

6、The shoulder of the sprocket wheel is specially designed and heat-treated accordingly, which will reduce the wear of the hardened chain.

7、Special conveyor disc has low friction coefficient and stable conveying capacity.

|

Model |

Motor Power (KW) |

Conveying (M3/h) |

Sprocket speed(r/min) |

| ZY-120 | 1.5-3 | ≤8 | 6-18 |

| ZY-160 | 2.2-5 | ≤19 | 6-18 |

| ZY-220 | 4-11 | ≤32 | 6-18 |

| ZY-270 | 5.5-15 | ≤52 | 6-18 |

| ZY-325 | 7.5-18.5 | ≤79 | 6-18 |

Application field of Chain Pipe conveyors

Fine chemicals: pigments, dyes, coatings, carbon black, titanium dioxide, iron oxide, ceramic powder, heavy calcium, light calcium, bentonite, molecular sieve, kaolin, silica gel powder, activated carbon and so on

Pesticide ores: urea, ammonium chloride, ammonium bicarbonate, soda powder, solid pesticides, tungsten powder, pesticide additives, copper concentrate powder, coal powder, phosphate rock powder, aluminum oxide powder, etc

Building materials: cement, terracotta, yellow sand, quartz sand, clay powder, silica, limestone powder, dolomite powder, wood powder, glass fiber, silica, talc powder, etc

Food industry: flour, starch, cereal, milk powder, food additives, etc

Send Inquiry

Copyright © 2025 Wanbon Boway Machinery Co., LTD. All rights reserved.

Chinese

Chinese Spanish

Spanish