News detail

What are Types and Characteristics of Pharmaceutical Packaging Machines?

Types and Characteristics of Pharmaceutical Packaging Machines

Pharmaceutical packaging machines play a crucial role in the pharmaceutical industry by efficiently and accurately packaging medications for distribution. These machines come in various types, each with its own unique characteristics and capabilities. In this article, we will explore the different types of pharmaceutical packaging machines and their key features.

1. Blister Packaging Machine:

Blister packaging machines are commonly used in the pharmaceutical industry to package solid medications, such as tablets and capsules. These machines form individual blister packs from a roll of plastic film and then fill them with the medication before sealing them. Blister packaging machines are known for their high speed and accuracy, making them ideal for high-volume production.

Key features:

– Automatic feeding and filling system for efficient operation

– Adjustable sealing and cutting mechanisms for different blister sizes

– PLC control system for precise control of the packaging process

– Optional features such as embossing and printing for branding and identification

2. Bottle Filling Machine:

Bottle filling machines are used to fill liquid medications into bottles of various sizes and shapes. These machines typically utilize a piston or peristaltic pump system to accurately dispense the correct amount of medication into each bottle. Bottle filling machines are versatile and can be used for a wide range of liquid medications, including syrups, suspensions, and solutions.

Key features:

– High-speed filling capability for rapid production

– Adjustable filling volume and speed for different bottle sizes

– Capping and sealing mechanisms for a complete packaging solution

– Easy-to-clean design for efficient maintenance and hygiene

3. Labeling Machine:

Labeling machines are essential for applying labels to pharmaceutical packaging, including bottles, boxes, and cartons. These machines can apply various types of labels, such as wrap-around, front-and-back, and top labels, with precision and accuracy. Labeling machines help pharmaceutical companies comply with regulatory requirements and ensure product traceability.

Key features:

– Automatic label feeding and application system for continuous operation

– High-speed labeling capability for efficient production

– Adjustable label placement and orientation for different packaging formats

– Integrated coding and printing systems for batch and expiry date information

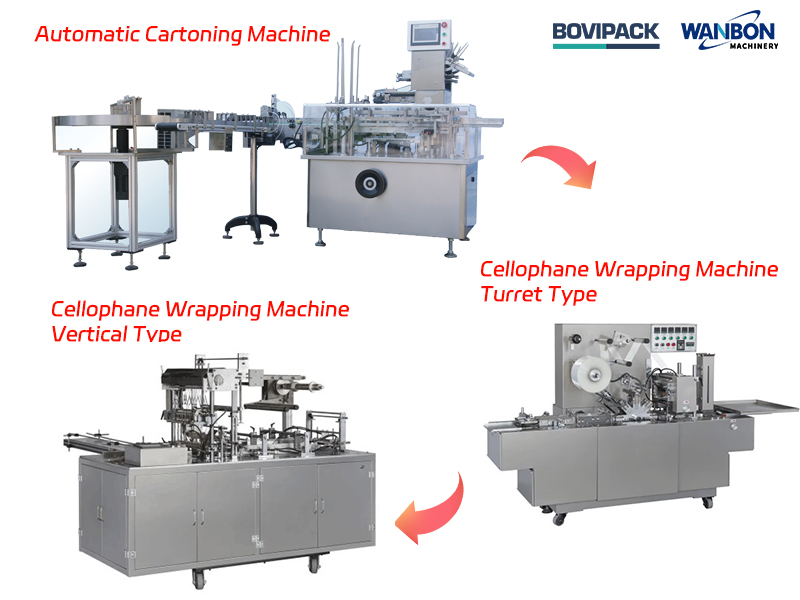

4. Cartoning Machine:

Cartoning machines are used to package pharmaceutical products into cartons or boxes for distribution. These machines can handle a variety of packaging formats, including blister packs, bottles, and tubes. Cartoning machines are essential for automating the packaging process and ensuring product safety and integrity.

Key features:

– Automatic carton feeding and forming system for seamless operation

– Multiple carton loading options, such as manual, automatic, and robotic

– Integrated leaflet insertion system for including product information

– Vision inspection system for quality control and defect detection

In conclusion, pharmaceutical packaging machines come in various types, each with its own unique characteristics and capabilities. From blister packaging machines for solid medications to bottle filling machines for liquid medications, these machines play a vital role in ensuring the safe and efficient packaging of pharmaceutical products. By understanding the different types of pharmaceutical packaging machines and their key features, pharmaceutical companies can choose the right equipment to meet their production needs and regulatory requirements.

Send Inquiry

Copyright © 2025 Wanbon Boway Machinery Co., LTD. All rights reserved.

Chinese

Chinese Spanish

Spanish