News detail

What problems may occur with heat shrink packaging?

Heat shrink packaging is a widely used method for packaging products in various industries. However, like any other packaging method, it is not without its challenges.

The following article will list some common problems that can occur during heat shrink packaging and possible solutions.

1. Uneven shrinkage: This occurs when the heat is not evenly distributed across the shrink film, resulting in wrinkles or uneven shrinkage of the packaged product.

Uneven shrinkage can be caused by several factors, such as improper heat distribution from the heat source or the use of low-quality shrink film.

Solution: To solve this problem, it is important to ensure that the heat is evenly distributed by using a heat tunnel or heat gun with adjustable settings.

Additionally, using high-quality shrink film can also help minimize the risk of uneven shrinkage.

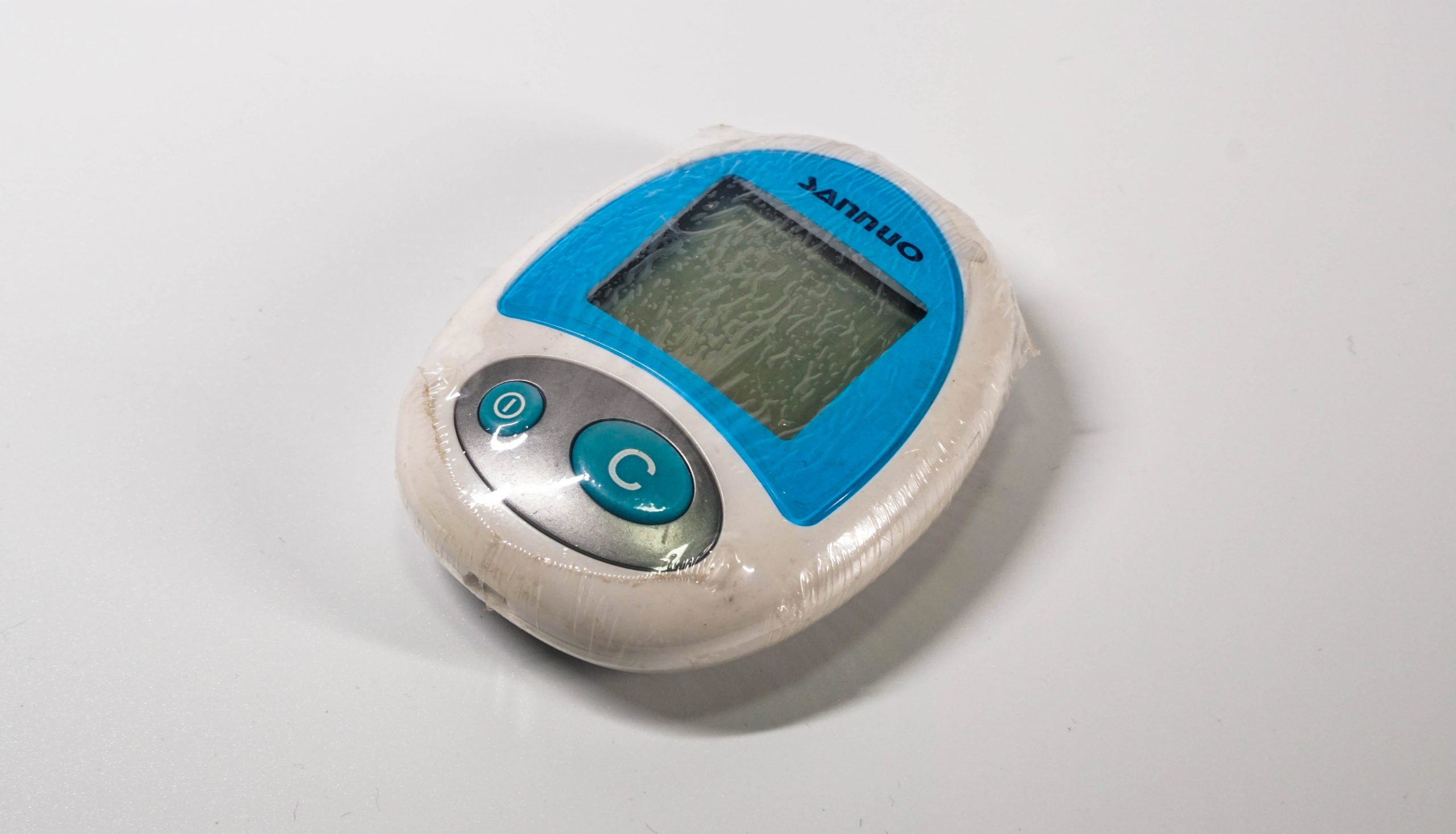

2. Air bubbles or Trapped air: Air bubbles can occur when the shrink film is not properly sealed or when there is excess air trapped inside the package.

This can result in a less visually appealing package and may also affect the integrity of the product.

Solution: To prevent the formation of air bubbles, it is crucial to make sure that the shrink film is tightly sealed around the product.

This can be achieved by using a heat sealer or by applying additional heat to the edges of the package to create a secure seal.

3. Deformation or Distortion: This occurs when the heat applied during the shrinking process is too high or when the product is exposed to heat for too long.

Solution: To avoid product deformation, it is important to carefully monitor the temperature and duration of the heat shrink process.

Using a temperature-controlled heat source and setting the appropriate shrink time can help prevent product deformation and ensure that the packaged product remains in its original form.

4. Burn marks: Burn marks can happen when the heat source is too close to the shrink film or when the heat is applied for too long.

This can result in unsightly marks on the packaging, which can affect the overall appearance of the product.

Solution: To prevent burn marks, it is essential to maintain an appropriate distance between the heat source and the shrink film.

Additionally, regularly checking the temperature of the heat source and adjusting it accordingly can also help prevent burn marks.

In conclusion, heat shrink packaging is a popular method for packaging products, but it is not without its challenges.

Uneven shrinkage, air bubbles, product deformation, and burn marks are common problems that can occur during the heat shrink process.

By understanding the causes of these problems and implementing appropriate solutions, such as using high-quality shrink film, ensuring proper sealing, monitoring temperature and duration, and maintaining a suitable distance between the heat source and shrink film, these issues can be minimized or eliminated, resulting in effective and visually appealing heat shrink packaging.

Send Inquiry

Copyright © 2025 Wanbon Boway Machinery Co., LTD. All rights reserved.

Chinese

Chinese Spanish

Spanish